Objective and Significance: –

Conventional reinforced concrete is a composite material of reinforcing steel bars embedded in a hardened concrete matrix. The accurate information on the properties of the reinforcing steels as a construction material is important at the design or construction stage. There are many codes which specify the limits on the properties and testing procedures of the steel rebar. These are ASTM A615, BS4449, ISO 6935-2 etc. Reinforcing bars tests in most construction sites have been restricted to tensile and bend tests with little or no information about chemical composition as they relate to the structural performances of the bars.

Chemical composition variations in producing reinforcing steel bars are unavoidable. Carbon is the main strengthening element that participates in two strengthening mechanisms, solid solution and second phase formation (cementite). Although carbon increasing the strength (mainly the tensile TS), but on the other hand decrease the ductility and Hardness, in addition to affecting the weldability. The

carbon equivalent represents the contribution of carbon and other elements to the formation of structures susceptible of hydrogen embrittlment during welding. Other properties of the rebar are compromised when the carbon steel with medium carb on content is used for fabricating rebar.

Influence of different chemical ingredients in steel on properties of rebars: –

- Carbon (C): – Higher carbon contributes to the tensile strength of steel, that is, higher load bearing capacity and vice versa. Lower carbon

content less than 0.1 percent will reduce the strength. Higher carbon content of 0.3 percent and above makes the steel bar unweldable and brittle. - Manganese (Mn): – Higher manganese content in steel increases the tensile strength and also the carbon equivalent property.

- Sulphur (S): – Presence of sulphur should be limited. Presence of higher sulphur makes the bar brittle during twisting, as higher sulphur content brings the hot shot problem during rolling.

- Phosphorus (P): – Higher phosphorus content contributes to the increase in strength and corrosion resistance properties but brings brittleness due to the formation of low euctoid phosphicles in the grain boundary. Also lowers the impact and value at subzero temperature level (transition temperature).

- Copper (Cu): -Being a pearlite stabiliser, it increases the strength and resistance corrosion property.

- Chromium (Cr): – Present as an impurity from the scrap and influences carbon equivalent; weldability and increases corrosion resistance property.

- Carbon Equivalent (CE or Ceq): – This property is required to set the cooling parameters in TMT (Thermo mechanically treated) process and a slight variation in carbon equivalent may alter the physical properties. In case of CTD (Cold twisted deformed) bars, carbon equivalent has a maximum limit of 0.42 percent but there is no lower limit prescribed. As such, as long as the chemical composition and physical properties of raw materials are within specified limits, the variation in carbon equivalent as in the case of TMT bars.

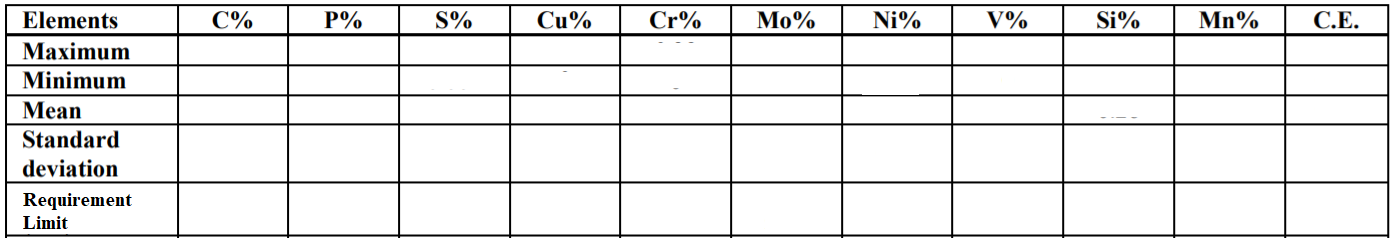

Procedure of the chemical analysis of the steel is done in certified lab and results are reported like below.

Results: –