Workability of concrete: –

Workability is a property of fresh concrete mixture. Workability means the ease of placement and workable concrete means the concrete which can be placed and can be compacted easily without any segregation. It possesses the property which can be easily placed and mould in to given shape.

Significance of workability: –

If concrete is not workable then its very hard to place that concrete. It may form pores concrete. Honeycombing may occur. Strength of the concrete may also be affected by the workability of concrete. Workability gives ease of work.

Factors affecting Workability: –

- Water Content of the Concrete Mix

- The Size of aggregates

- The shape of aggregates

- Surface texture of aggregates

- The porosity of aggregates

- Grading of aggregates

- Use of admixtures

- Ambient Temperature

Slump cone test: –

Slump test is the most commonly used method of measuring consistency of concrete which can be employed either in laboratory or at site of work. It is not a suitable method for very wet or very dry concrete. It does not measure all factors contributing to workability, nor it is always representative of the placeability of the concrete.

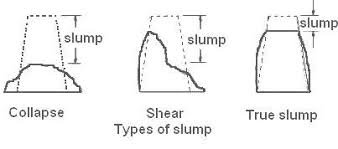

True Slump: – If the concrete slumps evenly it is called true slump.

Shear slump: – If one half of the cone slides down, it is called shear slump. In case of a shear slump, the slump value is measured as the difference in height between the height of the mould and the average value of the subsidence.

Collapse: – If a slum collapse the it is called as collapse slump. Any slump specimen which collapses or shears off laterally gives incorrect result and if this occurs the test shall be repeated with another sample.

Slumps For Various Concretes: –

| S.no. | Types of concrete | Slump |

| 1. | Concrete for road construction | 20 to 40mm |

| 2. | Concrete for tops of curbs parapets piers slab | 40 to 50 mm |

| 3. | Concrete for canal lining | 70 to 80mm |

| 4. | Concrete for arch and side wall | 90 to 100mm |

| 5. | Normal RCC work | 80 to 150mm |

| 6. | Mass concrete | 25 to 50mm |

| 7. | Concrete to be vibrated | 10 to 25mm |

Apparatus: –

Slump Cone

Tamping Rod: – To tamp the concrete

Scale: – For measuring the slump depth

Procedure

i) The internal surface of the mould is thoroughly cleaned and applied with a light coat of oil.

ii) The mould is placed on a smooth, horizontal, rigid and non-absorbent surface.

iii) The mould is then filled in four layers with freshly mixed concrete, each approximately to one-fourth of the height of the mould.

iv) Each layer is tamped 25 times by the rounded end of the tamping rod (strokes are distributed evenly over the cross-section).

v) After the top layer is rodded, the concrete is struck off the level with a trowel.

vi) The mould is removed from the concrete immediately by raising it slowly in the vertical direction.

vii) The difference in level between the height of the mould and that of the highest point of the subsided concrete is measured.

viii) This difference in height in mm is the slump of the concrete.