Consistency of cement

It is a minimum quantity of water requirement to start chemical reaction with cement to form a paste. Hence consistency test help to calculate minimum requirement of water to make cement paste.

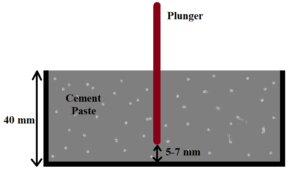

Standard Consistency: – Requirement of water for making cement paste can be found out by the plunger of the Vicat apparatus penetrating the cement paste about 5mm to 7mm from the bottom of Vicat mould.

Apparatus and Material requirement: –

Vicat Apparatus:- It has a frame with moveable rod with cap at one end. It has plunger which insert in cement paste. It has length scale to measure depths. It has a glass plate at base and mould for concrete paste.

Weighing Balance:- 1000 grams weigh scale with least count of 1gram.

Stop watch: – To measure Time.

Tray: – To make cement Paste.

Measuring cylinder: – To measure water. cylinder may be of 200 ml.

Procedure: –

- Check weather of the lab:- Lab temperature should be around 27 degree Celsius. Humidity should be around 65%.

- Take 300 grams of cement. Add water in it. Measure the Quantity of water added.

- Mix cement and water properly for 3 – 5 minutes. Make a good paste.

- Fill the Vicat Mould with Paste. Fill it to the edge. Smoothen the top surface of the paste.

- Remove air content in the mould with mild shakes.

- Immediately place the mould on Vicat apparatus base. Base should be smooth.

- Lower the Plunger to touch the top of paste and remove it quickly.

- Let the plunger go deep in the cement paste.

- Note the reading of the depth by plunger.

- It should be 33-35 mm. Means depth from bottom should be 5-7 mm, as mould is of 40 mm depth.

- If depth is more then try next sample with less quantity of water. If depth is less the try next sample with more water.

- Repeat these test until desired result is achieved.

Formula and Calculations: –

Percentage of water = ( Weight of water added / Weight of cement ) x 100

Example- If water added is 120 ml to form consistency in 300 grams of cement.

then,

Percentage of water = ( 120 / 300 ) x 100 = 40%